The Future of Spin-On Oil Filters

by Chris Lewis.

The microGreen filter utilizes the highest quality materials, including a silicone anti-drainback valve, high quality steel, and premium filter media. The microGreen oil filter is a direct replacement for OEM filters and installs and removes like a traditional filter, using premium materials and construction. It has the same specifications as a traditional spin-on oil filter-a steel base plate, standard attachment threads, standard filter sizes, and internal pressure relief valve.

Technology

The microGreen spin-on oil filter's advanced hybrid design combines two distinct filter elements within the same space as a traditional spin-on oil-filter. The filter media captures the larger particles in the engine oil, while the microfilter captures particles down to two microns in size, keeping your oil cleaner, longer.

How the Microfilter Works

The "two filters in one" design of the microGreen filter leverages a core conventional oil filter structure, allowing most of the oil to take its usual path while diverting a small portion of the oil to the top of the filter to be processed through our patented microfilter. The microfilter-which is constructed of advanced materials that provides advanced filtration efficiency.

To avoid disrupting the oil flow or adversely affecting oil pressure, the microfilter is designed to capture oil over multiple passes. By continuously filtering a small portion of the engine oil, the microGreen filter achieves improvements in oil quality over time and in as few as 100 miles of driving.

The microfilter also features a high pore volume with 2-5 micron-size pore openings. This enables the capture of a large amount of these small particles without clogging the filter, resulting in cleaner, longer lasting oil and an extended filter life.

Patented Technology

The microGreen vehicle engine oil filter is based on the patented technology for the Spin-On Microfilter System® (SOMS®). The microGreen filter is the subject of four issued U.S. patents with several more patents pending. In addition, the microGreen filter is also covered by issued and pending patents in many international jurisdictions.

Looking to the Future of Oil Filters with NYSERDA

Development of the microGreen oil filter was supported in part by a shared research agreement with the New York State Energy Research and Development Authority (NYSERDA). NYSERDA is a New York State public-benefit corporation with a mission to use innovation and technology to solve some of New York's most difficult energy and environmental problems in ways that improve the State's economy. NYSERDA has a multi-faceted set of programs to help develop and implement new energy and environmental programs and products that benefit New York State. Learn more at www.nyserda.org.

Testing & Validation

Photo Credit: CarCareTotal

The microGreen filter also exceeds OEM burst pressure requirements using SAE HS-806. This test ensures the quality and integrity of the filter canister and its resistance to leaking and splitting under extreme pressures.

Cleaner Oil, Guaranteed

ISO 4548-12 multi-pass tests have been conducted to determine the filtration efficiency and dirt holding capacity of the convention pleated full-flow filter element inside the microGreen filter. The results demonstrate that the microGreen filter exceeds the necessary performance requirements for extended use for both filtration efficiency and capacity.

Analyses have also been conducted to understand the quality of the oil film using the microGreen filter even after extended use of lubricating oil. The oil film is the thin coating of lubrication on the surface of the moving parts within the engine. By conducting a Pin-on-Disk (ASTM G99) test at an independent certified laboratory, the lubricity and protective properties of the oil were assessed. New oil, oil filtered by the microGreen filter for 72,000 miles and oil filtered by a conventional filter were analyzed. Results indicate that oil filtered by the microGreen filter has equivalent oil film quality to new oil.

microGreen on the Road: Proving our Filters Last Longer

MicroGreen filters have gone through more than 200 million miles of on-road testing. We've found that testing in actual vehicles and driving conditions is the most accurate reflection of filter performance.

During the testing, oil samples were taken directly from the engine before and after each testing interval, and sent to an independent oil analysis laboratory where the oil was analyzed for particulate contamination, wear metals, viscosity and overall chemistry. Particulates are the leading oil quality indicator for cleanliness.

The results indicate that not only can the microGreen filter effectively clean the oil; it maintains that cleanliness level to 30,000 miles. One car using the microGreen filter traveled over 72,000 miles without an oil change and demonstrated excellent results throughout. We have an estimated 1.8B miles of customer use of the MG oil filter.

Microfilters vs. Standard Filter Media

We installed each competitor's conventional oil filter in a passenger vehicle, and after traveling 40 miles with used, dirty engine oil, oil samples were taken. Then, those same conventional filters were fitted with an adapter to use the microfilter technology in the microGreen® oil filter, and the vehicles were operated another 40 miles. With the addition of the patented microfilter technology, the average five-micron particle count dropped an additional 85%.

Savings

Reduce Maintenance Costs

Whether you're weighing the options for your personal vehicle or commercial fleet, cost savings are critical. The microGreen spin-on filter reduces the costs associated engine maintenance by extending the use of the engine oil.

Additionally, through the increased capture of small particles, our oil filters can help reduce wear on your vehicle's engine. This impact on engine life can result in decreased maintenance associated with wear and provide indirect savings potential.

Fleets can also benefit from additional cost savings by taking into account the decreased vehicle downtime due to reduced maintenance time. Download our cost savings calculator to learn more about how using microGreen filters can yield potential materials and labor savings for fleets.

Reduce Waste

Used oil and used oil filters, which contain toxic substances such as benzene, lead, zinc and cadmium, are considered one of the highest environmental impact concerns, threatening drinking water and the earth.

It is estimated that annual U.S. lubricating oil sales exceed 600 million gallons-and the EPA approximates that "do it yourself" oil changes generate an excess of 200 million gallons of used oil each year. It is also estimated that the U.S. generates more than 485 million used oil filters yearly, and despite many states' mandates to recycle used filters, the recycling rate remains around 50%. Millions of filters containing toxic used oil are being discarded improperly, posing serious potential hazards to drinking water. To put the danger in perspective, a single gallon of used oil pollutes one million gallons of water, equivalent to the water supply consumed by 50 people in one year.

microGreen helps to alleviate the environmental impact generated by the use of engine oil and oil filters. Because our filters clean oil more efficiently and are longer-lasting than traditional filters, vehicle owners are able to use fewer filters and significantly less oil over the course of a vehicle's lifetime. This reduced frequency of oil changes and filter replacements has the potential to prevent a significant amount of hazardous waste going into our landfills.

Reduce CO2 Emissions

An independently conducted Life Cycle Analysis (LCA)* demonstrates the environmental impacts of using microGreen spin-on oil filters. The findings indicate that our premium oil filters have a significant impact on the reduction of CO2 emissions, compared to conventional oil filters. Specifically:

- Using a microGreen filter can yield savings of 55-104 kilograms of CO2 over 30,000 miles, compared to equivalent size conventional spin-on filters that are changed every 3,000-5,000 miles, respectively.

- These savings are equivalent to 19.79 pounds of CO2 per gallon of oil.

- Overall, microGreen filters contribute to a 75-85% reduction in CO2 emissions.

Use

We've designed our filters to be simple to use-they're installed and removed just like conventional oil filters, making engine oil maintenance easy and more cost effective.

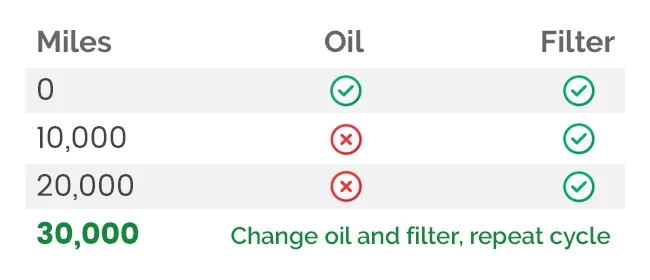

When the vehicle is due for an oil change, simply change the oil and spin on a microGreen filter, just like you would a traditional filter. Our high performance filters enable you to drive up to 30,000 miles without needing to change the oil.

- At the 10,000-mile oil change interval, only the microGreen® filter should be changed-the oil should remain in the engine and simply topped-off as necessary.

- At the 20,000-mile oil change interval, repeat the process. Change the filter, let the oil remain and top-off as necessary.

- After 30,000 miles, both the filter and the oil should be changed.

- Two filters in one system, keeping oil cleaner - longer.

- Patented microfilter captures particles down to 2 microns.

- 65-70% reduction in oil maintenance costs.

- 70% reduction in oil use.

- U.S. patents issued: 6,605,215 and 7,048,848.

microGreen recommends that no matter what brand of oil filter you use, or whatever oil maintenance interval you follow, that you should check the engine oil level of your vehicle at least monthly to ensure optimal operation.

|

|

|

|

About Chris Lewis.

Chris Lewis is a passionate individual with a deep affinity for the world of automobiles. From a tender age, his fascination with cars was nurtured by his father, a seasoned mechanic based in the vibrant city of San Francisco. Growing up under the watchful guidance of his skilled father, Chris developed an early aptitude for all things automotive.

Thoughts on "The Future of Spin-On Oil Filters"

|

|

|

|

Get FREE Filters now. Or latest free tools from our best collections.

Disable Ad block to get all the secrets. Once done, hit any button below

|

|

|

|